The Challenge

Continuous online monitoring of bushings provides real-time information which can result in the early detection of a possible failure.

A prominent U.S. utility was looking for a way to improve system reliability for their 138kV assets. They researched and reviewed options available on the market that included affordable bushing monitoring. After review, the utility chose to pilot the Dynamic Ratings’ C50 Transformer Monitor to see if it was worth the investment to become part of the overall solution.

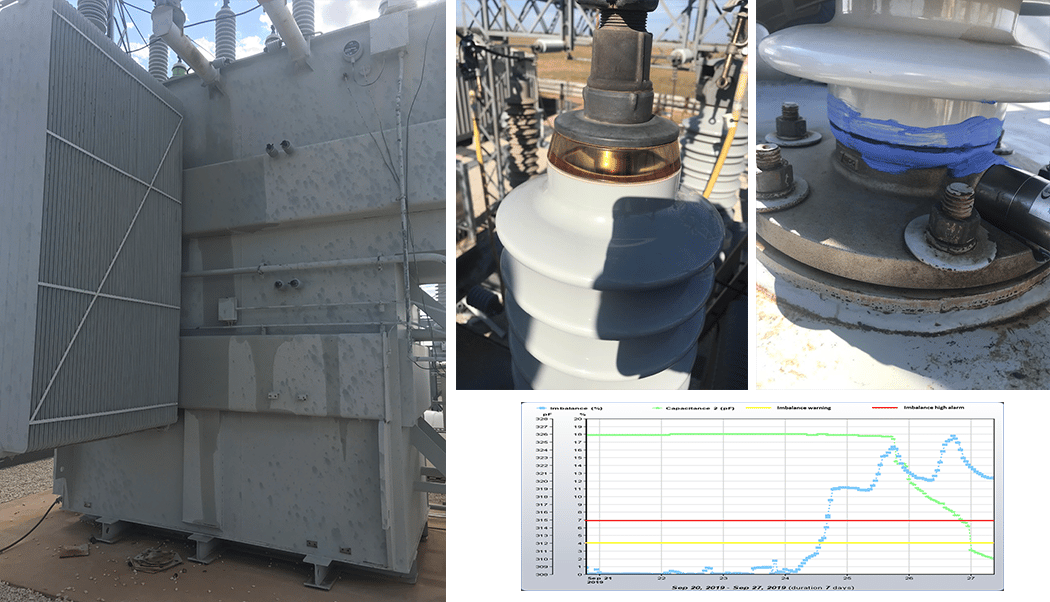

The C50 Transformer Monitors were installed and serviced on the transformers by Dynamic Ratings Field Engineers. One day, after about two years in service, the utility received notification of a major alarm happening at one of the C50 installation sites. Upon further review of the online web pages, the C50 indicated that there was a rapid change happening in the health of a bushing on the transformer.

The Solution

Dynamic Ratings engineering team took a closer look at the data and recommended that the utility inspect the bushings for a possible oil leak. Low oil in the bushing would explain the decrease in the C1 capacitance of the bushing.

The utility dispatched an engineer to investigate the alarm and to look for any signs of an oil leak. During the investigation, the engineer noticed there was no oil present in the sight glass.

Upon further inspection, he saw that oil had leaked out of the bushing and down the side of the transformer.

The Result

Dynamic Ratings C50 Transformer Monitor was able to detect and notify the utility of a problem with the bushing. Dynamic Ratings team of experts was able to work closely with the utility to determine the problem and prevent a potential bushing failure. The utility was satisfied with their investment into bushing monitoring because it helped to potentially extend the life of their asset, improve situational awareness, save money and improve safety.

Continuous online monitoring of bushings with the C50 Transformer Monitor offers real-time information of bushing capacitance and power factor. It provides

- Temperature correlation

- Discrete readings

- Diagnostic web pages

- Diagnostic Software

- Superior Sensor Design